In recent years, with the improvement of aggregate grade standards, higher-quality and better-shaped aggregates have been favored by the broad market and have become the pursuit of more crushing production line investors. Why do we need to reshape the aggregate?

Take limestone as an example. Limestone is a kind of sedimentary rock and belongs to a hierarchical structure. In the crushing production line, after being crushed by the jaw crusher, the limestone is crushed along its natural bedding, so a large number of machine-made stones produced in this way are needle-shaped. Too many needle-like aggregates will not only make the workability of fresh concrete worse, but also greatly reduce the compressive strength of concrete and damage the stability of construction facilities.

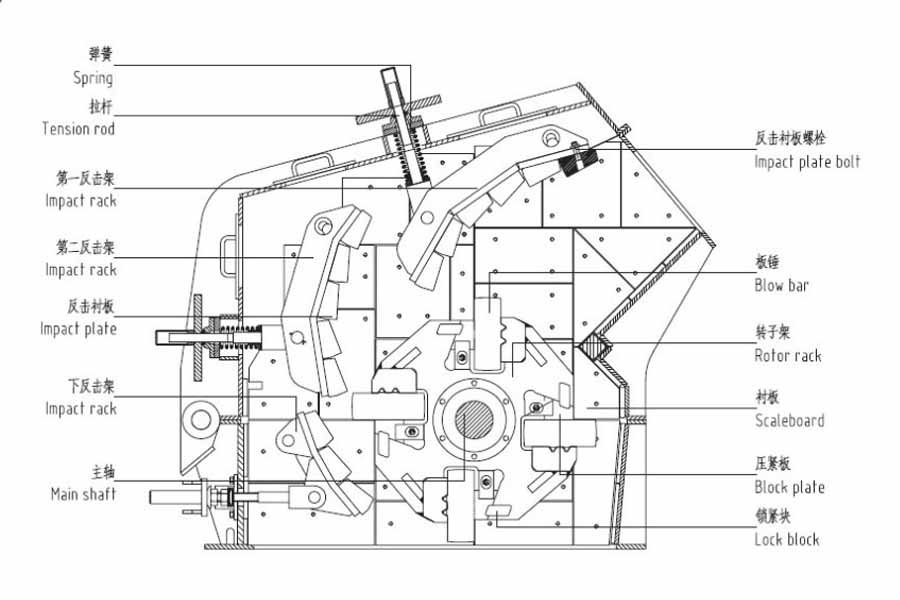

The difference between impact crusher and vertical shaft impact crusher

The principle of impact crushing is that when the material is repeatedly impacted between the hammer and the impact plate, the materials are also frictional and collided with each other. The crushing and optimization of the shape are both considered, and the needle-shaped aggregate is less. The impact crusher is mostly deployed in the crushing production line for medium hardness and soft materials, its feed size is less than or equal to 500 mm, which can be directly placed after the jaw crusher. The output size is generally 3-60 mm, and the powdery material is less.

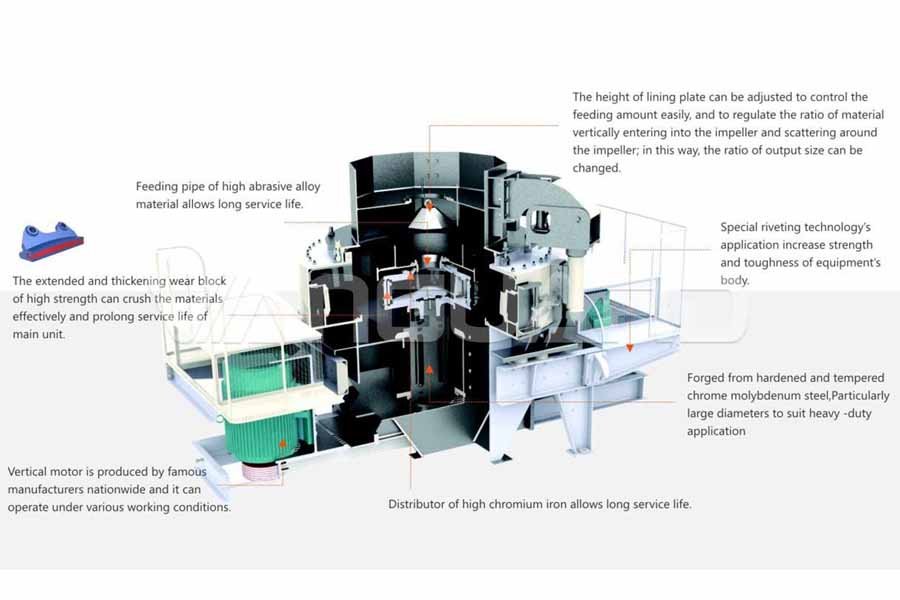

Vertical shaft impact crusher is also called sand making machine, which is also widely used in stone shaping and sand production. The unique rotor design and optimized bypass feeding system greatly improve the production capacity and output quality, while also reducing production costs and wear parts consumption. The sand making machine is suitable for all kinds of soft, medium hardness and high hardness materials, but the feed size is less than 40 mm, and it is suitable for small particle size materials that have been crushed and processed. The output size is generally less than 5 mm.

Russian customer crushing plant site

Production configuration: vibrating feeder+ jaw crusher+ impact crusher+ vibrating screen

Capacity:100TPH

According to the Russian customer's requirements, Vanguard engineers designed a limestone crushing production line with jaw crusher + impact crusher. The aggregates produced have a relatively high proportion of large particle size and good shape. They are high-quality road paving aggregates. The simple configuration of jaw crusher and impact crusher can not only maximize production capacity, save investment, and help customers recover investment as soon as possible. Vanguard Machinery adheres to the principle of serving customers, satisfying customers and designing the most suitable production plan for customers as the ultimate goal, to get win-win cooperation and be hand in hand with customers.