1. Jaw Crusher

(1). Introduction To Jaw Crusher:

It is mainly used for crushing various medium-hard ore and rock that compressive strength does not exceed 250MPa. It has a large crushing ratio, high output, and products. Uniform particle size, reliable work, easy maintenance, low operating cost, etc. It is widely applied in many industries such as mining, smelting, construction, highway, railway, water conservancy, and chemical industry, etc.

(2). Working Principle Of Jaw Crusher (Take PE Jaw Crusher As An Example):

Powered by an electric motor, driven through the pulley, the V-belt and sheave drive eccentric shaft, so that the movable jaw predetermined trajectory reciprocated to crush the material enter crushing cavity composed of fixed jaw plate, movable jaw plate, and side guard plate, then the final product material is discharged through the lower discharge port. The crushing method of this series of jaw crusher is a curved extrusion type, in which a motor-driven belt and pulley that movable jaw is moved up and down through the eccentric shaft. When the movable jaw rises, the angle between the toggle plate and the movable jaw becomes larger, thereby pushing the movable jaw plate approaches the fixed jaw plate, meanwhile, the material is squeezed, rubbed, ground, etc. When the movable jaw moves downward, the angle between the toggle plate and the movable jaw becomes smaller, the movable jaw plate is under the action of the pull rod and spring leaving the fixed jaw plate. The crushed materials are discharged from the lower opening of the crushing cavity. With the motor continuously rotated, realizing mass production by movable jaw's periodic crushing and discharging material.

(3).VANGUARD Jaw Crusher Series Products:

(4). Site Atlas

2. Cone Crusher

(1)Introduction Of Cone Crusher:

There are many types of cone crusher, which can be adapted to a variety of crushing processes. It is widely applied in medium crushing to super fine crushing and is often used in the second and third crushing links of the production line. The cone crusher has a reliable structure and high production efficiency. It is usually suitable for processing hard stones, such as river stone, granite, basalt, iron ore (and other metal ores), quartz stone, etc. The cone crusher is a piece of ideal equipment for crushing hard ores, which are widely applied in metallurgy, construction, hydropower, transportation, chemical, building materials, and other industries.

(2) Working Principle Of Cone Crusher:

The cone crusher adopts the principle of lamination crushing, using the concave to continuously move to the crushing wall, squeezing the material sandwiched between the two to crush it.

(3) Vanguard Cone Crusher Series Products:

(4) Site Atlas

3. Vibrating Screen

(1) Introduction Of Vibrating Screen:

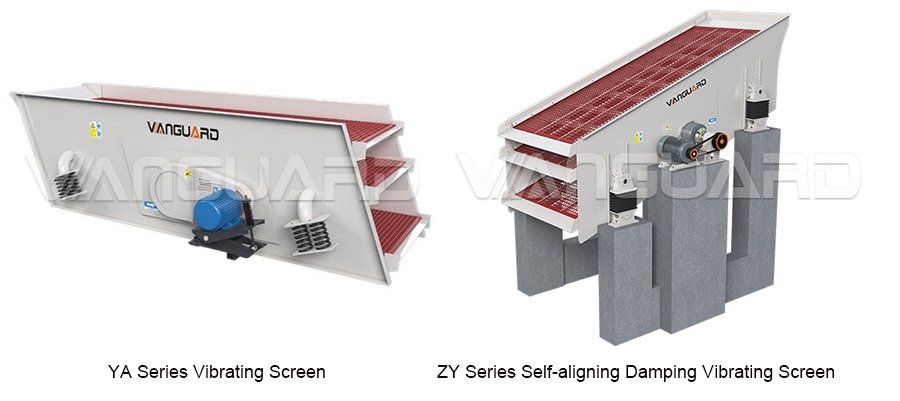

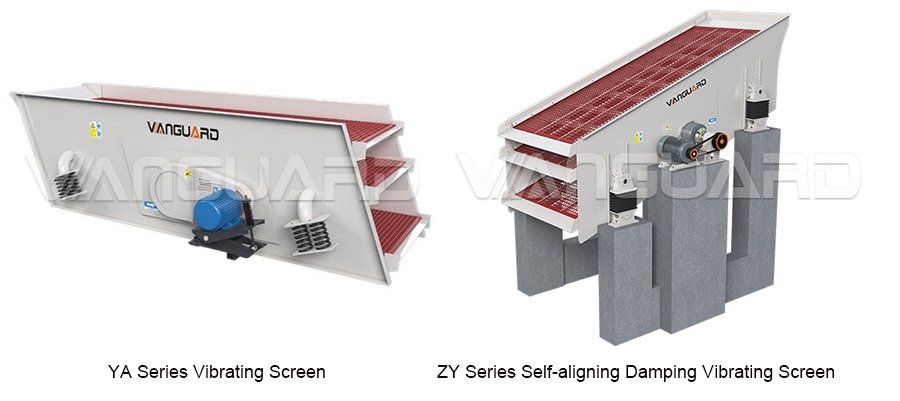

There are two kinds of vibrating screen: YA series vibrating screen and ZY Series self-aligning damping vibrating screen, mainly used for screening in mining, building materials, transportation, energy, chemical, and other industries.

(2). Working Principle Of Vibrating Screen:

By a motor that uses V-belt, the exciter's eccentric block rotates at high speed. Rotating the eccentric block will generate a large centrifugal force and stimulates the screen box to produce a certain range of circular motion. The material on the screen is transmitted by pulses on the surface of the inclined screen and produces a continuous throwing action. When the material passes through the screen surface, the particles smaller than the mesh pass through the screen to achieve sieving.

(3). VANGUARD Vibrating Screen Series Products:

1) YA Series Vibrating Screen:

The YA series vibrating screen has a long screen line, which is suitable for screening various specifications products. The vibrating screen adopts a barrel-type eccentric shaft vibration exciter and eccentric block to adjust the swing. It has the characteristics of reliable structure, strong exciting force, high screening efficiency, low vibration and noise, durability, convenient maintenance, and safe operation.

2) ZY series self-adjusting damping vibrating screen:

The ZY series self-adjusting damping vibrating screen adopts an independent modular design, which can quickly replace parts and minimize downtime; the self-centering design effectively corrects the screens with different centers of work vibration, greatly extending the service life of the equipment.

(4) Site Atlas

4. ball mill

(1). Introduction To Ball Mill

The ball mill is the key equipment for pulverizing materials after they are crushed. Ball mill is suitable for grinding various ore and other materials. It is widely used in Beneficiation, building materials, and chemical industries. It can be divided into dry and wet grinding methods.

(2). The Working Principle Of Ball Mill:

The working principle of the overflow type ball mill is mainly supported by rolling bearings, through the cylinder is rotated by the transmission mechanism, and the material is fed from the feeding place. In the cylinder, the material completes the operations of throwing, collision, impact, and self-grinding together with the steel ball to realize the material is ground. Due to the continuous feeding of materials, the pressure will cause the materials in the cylinder to gradually discharge from the feeding end to the discharge end. When the slurry is higher than the lower edge of the hollow shaft at the discharge end, the material will overflow by itself, and at the discharge end. The steel balls and coarse materials will be returned to the mill by the reverse spiral blades, where they will be crushed and ground.

(3). Vanguard Ball Mill Products:

(4). Site Atlas

(1). Introduction To Jaw Crusher:

It is mainly used for crushing various medium-hard ore and rock that compressive strength does not exceed 250MPa. It has a large crushing ratio, high output, and products. Uniform particle size, reliable work, easy maintenance, low operating cost, etc. It is widely applied in many industries such as mining, smelting, construction, highway, railway, water conservancy, and chemical industry, etc.

(2). Working Principle Of Jaw Crusher (Take PE Jaw Crusher As An Example):

Powered by an electric motor, driven through the pulley, the V-belt and sheave drive eccentric shaft, so that the movable jaw predetermined trajectory reciprocated to crush the material enter crushing cavity composed of fixed jaw plate, movable jaw plate, and side guard plate, then the final product material is discharged through the lower discharge port. The crushing method of this series of jaw crusher is a curved extrusion type, in which a motor-driven belt and pulley that movable jaw is moved up and down through the eccentric shaft. When the movable jaw rises, the angle between the toggle plate and the movable jaw becomes larger, thereby pushing the movable jaw plate approaches the fixed jaw plate, meanwhile, the material is squeezed, rubbed, ground, etc. When the movable jaw moves downward, the angle between the toggle plate and the movable jaw becomes smaller, the movable jaw plate is under the action of the pull rod and spring leaving the fixed jaw plate. The crushed materials are discharged from the lower opening of the crushing cavity. With the motor continuously rotated, realizing mass production by movable jaw's periodic crushing and discharging material.

(3).VANGUARD Jaw Crusher Series Products:

(4). Site Atlas

2. Cone Crusher

(1)Introduction Of Cone Crusher:

There are many types of cone crusher, which can be adapted to a variety of crushing processes. It is widely applied in medium crushing to super fine crushing and is often used in the second and third crushing links of the production line. The cone crusher has a reliable structure and high production efficiency. It is usually suitable for processing hard stones, such as river stone, granite, basalt, iron ore (and other metal ores), quartz stone, etc. The cone crusher is a piece of ideal equipment for crushing hard ores, which are widely applied in metallurgy, construction, hydropower, transportation, chemical, building materials, and other industries.

(2) Working Principle Of Cone Crusher:

The cone crusher adopts the principle of lamination crushing, using the concave to continuously move to the crushing wall, squeezing the material sandwiched between the two to crush it.

(3) Vanguard Cone Crusher Series Products:

(4) Site Atlas

3. Vibrating Screen

(1) Introduction Of Vibrating Screen:

There are two kinds of vibrating screen: YA series vibrating screen and ZY Series self-aligning damping vibrating screen, mainly used for screening in mining, building materials, transportation, energy, chemical, and other industries.

(2). Working Principle Of Vibrating Screen:

By a motor that uses V-belt, the exciter's eccentric block rotates at high speed. Rotating the eccentric block will generate a large centrifugal force and stimulates the screen box to produce a certain range of circular motion. The material on the screen is transmitted by pulses on the surface of the inclined screen and produces a continuous throwing action. When the material passes through the screen surface, the particles smaller than the mesh pass through the screen to achieve sieving.

(3). VANGUARD Vibrating Screen Series Products:

1) YA Series Vibrating Screen:

The YA series vibrating screen has a long screen line, which is suitable for screening various specifications products. The vibrating screen adopts a barrel-type eccentric shaft vibration exciter and eccentric block to adjust the swing. It has the characteristics of reliable structure, strong exciting force, high screening efficiency, low vibration and noise, durability, convenient maintenance, and safe operation.

2) ZY series self-adjusting damping vibrating screen:

The ZY series self-adjusting damping vibrating screen adopts an independent modular design, which can quickly replace parts and minimize downtime; the self-centering design effectively corrects the screens with different centers of work vibration, greatly extending the service life of the equipment.

(4) Site Atlas

4. ball mill

(1). Introduction To Ball Mill

The ball mill is the key equipment for pulverizing materials after they are crushed. Ball mill is suitable for grinding various ore and other materials. It is widely used in Beneficiation, building materials, and chemical industries. It can be divided into dry and wet grinding methods.

(2). The Working Principle Of Ball Mill:

The working principle of the overflow type ball mill is mainly supported by rolling bearings, through the cylinder is rotated by the transmission mechanism, and the material is fed from the feeding place. In the cylinder, the material completes the operations of throwing, collision, impact, and self-grinding together with the steel ball to realize the material is ground. Due to the continuous feeding of materials, the pressure will cause the materials in the cylinder to gradually discharge from the feeding end to the discharge end. When the slurry is higher than the lower edge of the hollow shaft at the discharge end, the material will overflow by itself, and at the discharge end. The steel balls and coarse materials will be returned to the mill by the reverse spiral blades, where they will be crushed and ground.

(3). Vanguard Ball Mill Products:

(4). Site Atlas