The 5X new sand making machine is modified and upgraded on the basis of the traditional vertical shaft sand making machine. Through the design of each part and the use of wear-resistant materials, the overall performance of the crusher is further improved. It is suitable for soft or medium hard and sand making and shaping of extremely hard materials are widely used in industrial fields such as building materials, chemicals, metallurgy, electric power, coal, and mining.

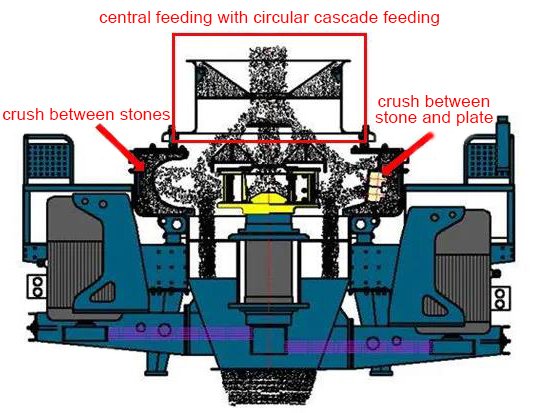

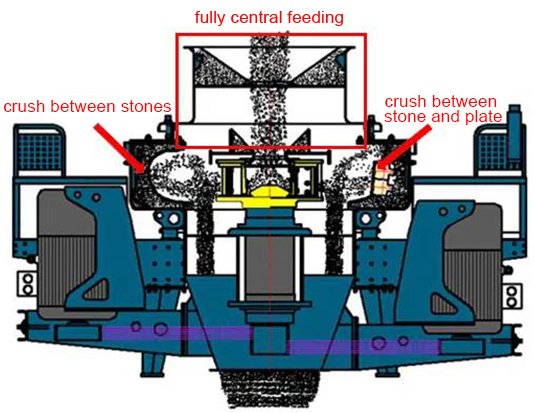

The 5X new sand making machine uses high-speed moving materials to crush each other and the friction between the materials to crush. The 5X new sand making machine can not only crush stones, but also reshape it. According to the feeding method of the material, the feeding method of the 5X new sand making machine can be divided into According to the feeding method of the material, the feeding method of the 5X new type sand making machine can be divided into fully central feeding and central feeding with circular cascade feeding. According to the compressive strength and abrasiveness of the material, the crushing methods of the 5X new sand making machine can be divided into crushing between stones and crushing between stone and plate.

1.Crushing between stones in the central feeding with circular cascade feeding mode:

The material enters the crusher through the feed hopper falls into the crusher. And it is divided into two parts by the distribution tray falls on the distribution tray via the bulk material cone or bulk tray. A part of it enters the spinning wheel at high speed from the middle of the material distribution plate. It is rapidly accelerated in the spinning wheel and then is projected out of the spinning wheel flow channel at high speed.

These materials are first impacted and crushed with another part of the falling materials around the distribution tray, and then impacted together on the material lining of the crushing chamber. After being bounced, they are impacted diagonally upwards to the top of the crushing chamber, changing direction and moving downwards. The emitted material forms a continuous material curtain. In this way, a piece of material is crushed by repeated impacts, friction and grinding in the crushing cavity. The crushed materials leave the crushing cavity under the action of gravity and enter the lower casing unloading hopper for discharge.

The upper and lower strike guard plate is installed on the wall of the crushing chamber to protect the casing from impact and abrasion. It is characterized in that the material is accelerated by the throwing wheel when accelerating, and about half of the particles get energy in the throwing wheel and then impact or rub against the falling material and the lining layer and make a high-speed impact and crush between the materials.

2.The crush between stone and plate in central feeding with circular cascade feeding mode:

The basic working principle is the same as the crush between stones in central feeding with circular cascade feeding mode. The difference is that the crushing cavity is installed with a beating guard plate during crushing between stones, the material forms a lining around it, and the material impacts on the material liner to be broken, and when crushing between stone and plate, the guard plate is beaten down and replaced. As a peripheral guard plate, the material is directly impacted on the peripheral guard plate and crushed.

3.The crush between stones in the fully central feeding mode:

The basic working principle is the same as crushing between stones in the central feeding with circular cascade feeding mode. The difference is that the bulk material cone or bulk material tray is unloaded or completely opened when the material is completely centered. All the materials fall directly into the distribution tray from the feed opening, and directly enter the spinning wheel through the middle of the distribution tray.

4.Crushing between stone and plate in the fully central feeding mode:

The basic working principle is the same as that of crushing between stone and plate in the central feeding with circular cascade feeding mode. The feeding method is complete center feeding, that is, the bulk material cone or bulk tray is unloaded or completely opened. All the materials fall directly into the distribution tray from the feed inlet, and directly enter the spinning wheel through the middle of the distribution tray.

Advantages of Vanguard 5X new type sand making machine:

1. Excellent product shape

Product with cubic grain shape, reasonable gradation, and adjustable fineness modulus. Especially suitable for artificial sand making and stone shaping.

2.Low consumption of wearing parts

The dual-throwing combination design of the rotor can greatly extend the wear time and protect the rotor body from excessive wear and tear. In addition, the alloy wear-resistant block is made of highly wear-resistant and high-temperature resistant materials used in important industries in the United States with low consumption and long life.

3.Automatic detection, safe and efficient

It uses a PLC control system, intelligent and efficient, reducing the difficulty of operation during use and the training time of operators.

4.Eco-friendly with less dust

It adopts a closed design that the materials impact and crush each other by themselves, which do not directly contact the metal components in the equipment but are crushed by impact and friction with the lining. It eliminates dust pollution by the ingenious airflow inside the vortex cavity circulation.

5. Convenient adjustment of the feed inlet

It is designed and installed a movable flow controller in the lower part of the feeding cavity. By adjusting the screw outside the feeding cavity to achieve the purpose of adjusting the size of the feeding port.

6.One machine with multiple functions, flexible application

It has a variety of crushing methods that multiple uses to realizes the flexible mode of the crush between stones and crush between stone and plate modes to meet the crushing needs of different materials.

7.Thin-oil lubrication system, automatic maintenance

5X new type sand making machine adopts thin oil automatic smoothing system, and dual oil pumps complement each other to ensure oil supply; Automatic shutdown without oil flow and pressure; Wind (water) cooling down; In winter, the motor is heated to start with a good smooth effect, which effectively solves the problems of bearing heating, keeps the spindle bearing at a constant temperature, and extends the maintenance cycle and service life.

Vangurd customer production site case 1:

Raw materials:river stone

Capacity:150 t/h

Auxiliary equipment: feeder, jaw crusher, cone crusher , sand making machine, vibrating screen

Vangurd customer production site case 2:

Raw materials: river stone

Capacity:300 t/h

Auxiliary equipment: feeder, jaw crusher, cone crusher , sand making machine, vibrating screen

Vanguard is a professional mining machinery manufacturer integrating production, R&D, design, sales, and after-sales constantly innovating and improving with mature technology, sophisticated craftsmanship, and reliable equipment quality. It can match reasonably according to customer needs. Meet the different process requirements of customers.