With the acceleration of urban infrastructure, people's demand for sand and gravel aggregates has gradually increased. The importance of the impact crusher is self-evident, as one of the commonly used equipment in the sand and gravel aggregate production line. Next, Vanguard Machinery will take you to understand the impact crusher.

Impact crusher is usually used in the second crushing production line process, which can crush materials with side length not exceeding 500mm and compressive strength not exceeding 350Mpa (European type 300Mpa). The impact crusher is suitable for crushing materials below medium hardness, and can also be used as a shaping machine to shape materials.

Working principle of impact crusher:

Impact crusher is a crushing machine that uses impact energy to crush materials. When working, the motor rotates at a high speed to drive the rotor to move at a high speed. When the material enters the machine from the inlet, it is crushed by the high-speed impact of the hammer on the rotor, and then crushed again by throwing on the impact liner, final re-crushed by bouncing back from the impact liner to the hammer plate area. In this process, the materials also collide with each other to achieve the effect of crushing. This process is repeated until the material is crushed to the required size and discharged from the discharge port.

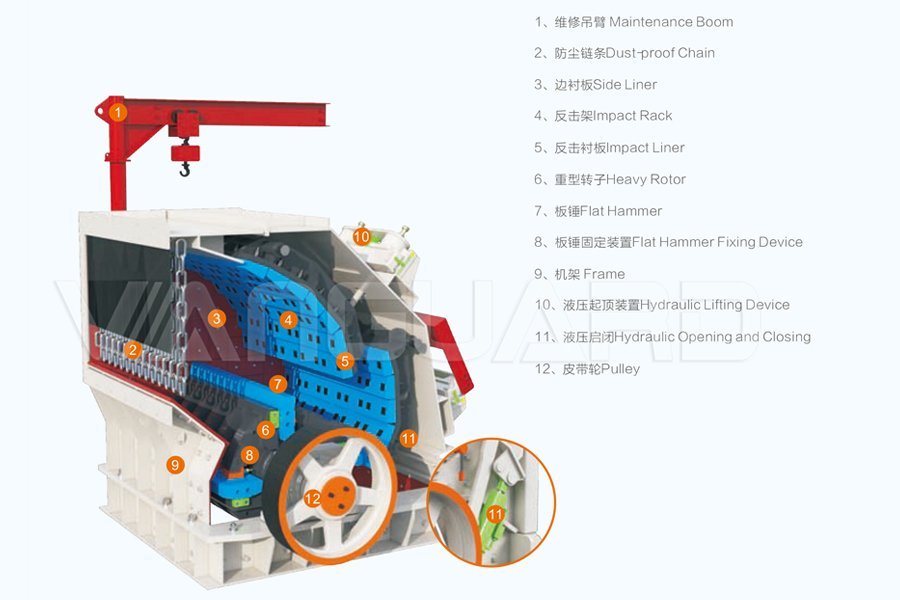

Introduction of main components of impact crusher

Opening and lifting device

There are usually two ways to opening and lifting device: one is the screw open and lift device; The other is a hydraulic lifting device. The crushing area and crushing equipment of the impact crusher are all inside the body. Therefore, to repair the internal equipment, a topping device is required to open the impact crusher. The general opening method is to open the upper frame of the impact crusher and then enter repair the inside of the machine.

Impact liner

The function of the impact liner is to withstand the impact of the material hit by the plate hammer, and to bounce the material back to the impact area, and be crushed in repeated impacts until obtained the desired product size. There are many forms of impact liner, which are divided into broken line impact liner, arc-shaped impact liner, forward impact liner, and backward impact liner. There are mainly two types: broken line and arc. The inner envelope of the broken line impact board is similar to involute particles, and the material at each point is impacted in an approximate vertical direction, so a better crushing effect can be obtained. The arc-shaped impact plate can make the material bounce off the impact plate and form a fierce impact crushing in the center area to increase the free impact crushing effect of the material.

Plate hammer and fixing method

The impact crusher's blow bars are divided into straight plate type blow bars and crescent type blow bars. The crescent type blow bar is better, which can ensure the vertical impact of the material, the impact force is large, and the crushing efficiency is high; The impact surface is also larger and more durable than the linear hammer. There are three ways to fix the hammer: bolt fixation, pressure plate fixation and wedge fixation. Generally, the crescent hammer is fixed by a wedge; Straight plate hammers are mostly fixed by pressing blocks. Usually during operation, under the action of centrifugal force, the wedge fixing method can ensure that the faster the rotor speed, the stronger the fixing of the hammer, and the more convenient disassembly and replacement.

Advantages of Vanguard Impact Crusher

1.The impact crusher has a large reduction ratio and good crushing affect. The product is cubic without surface tension and cracks, and quite good grain shape.

2.Using a hydraulic lifting device, it can quickly complete the replacement of vulnerable parts such as hammers, reducing downtime and maintenance time, thereby reducing maintenance costs.

3.It is convenient and quick that adopt hydraulic opening and closing and hydraulic adjustment devices to adjust the gap between the rotor and the impact plate to adjust the discharge size flexibly.

4.Adopting heavy-duty rotor design for greater rotational inertia, it has greater crushing force with higher efficiency at the same speed.

5. The plate hammer adopts the axial limit device fixed by the wedges, so that the faster the rotor speed, the stronger the plate hammer is fixed, the use is safe and reliable, and the replacement is more convenient.

6.The use of crescent-shaped blow bars can increase the thickness and height of the action part of the blow bars (the side shape can be observed)with greater crushing efficiency.

7.Two-cavity and three-cavity models can be selected to meet the crushing requirements of coarse, medium and fine crushing operations.

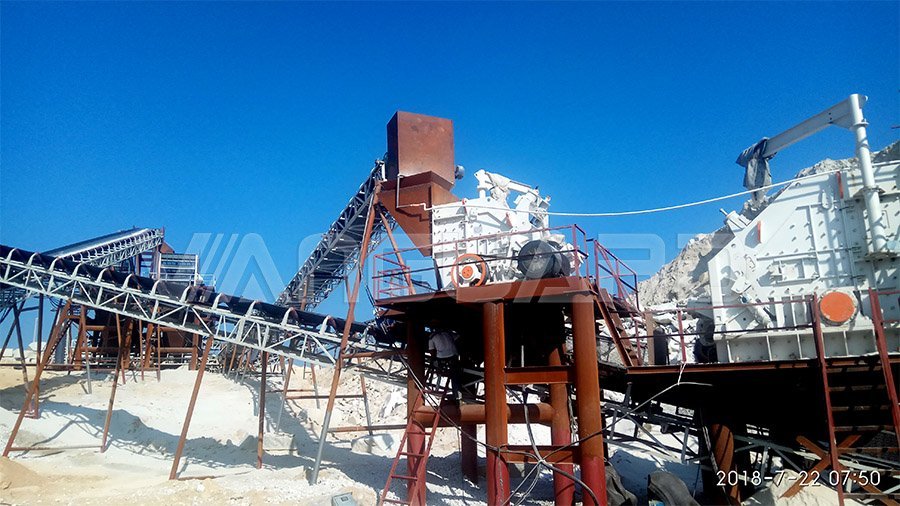

Vanguard customer case

Materials:construction waste

Capacity:250 T/H

Auxiliary equipment:VPE mobile crushing plant + VPF mobile crushing plant

Impact crusher customer site

Vanguard adapts to the diversified needs of customers to provide customers with reasonable matching and selection and customize the plan according to the customer's budget, processing materials, and the size of the finished product. At the same time, it provides services such as equipment installation, commissioning, and professional technical training.